Manufacturing parts using [now] traditional CNC often requires that you purchase tens or a hundred parts in order that the per-part price is reasonable. When you need 2 or 3 complex parts, traditional CNC is often not cost effective.

I needed to make a few headpieces for Steinberger (headless) guitars, and my original sources had disappeared. I created 3D models (using OpenSCAD), made test prints (in resin), and then uploaded the final models to Shapeways so that they could print the parts in metal. My per-part cost is now under $30, which is quite reasonable. The price is good because the part is small and complex (3D printing costs are based on amount of material used, without regard to part complexity).

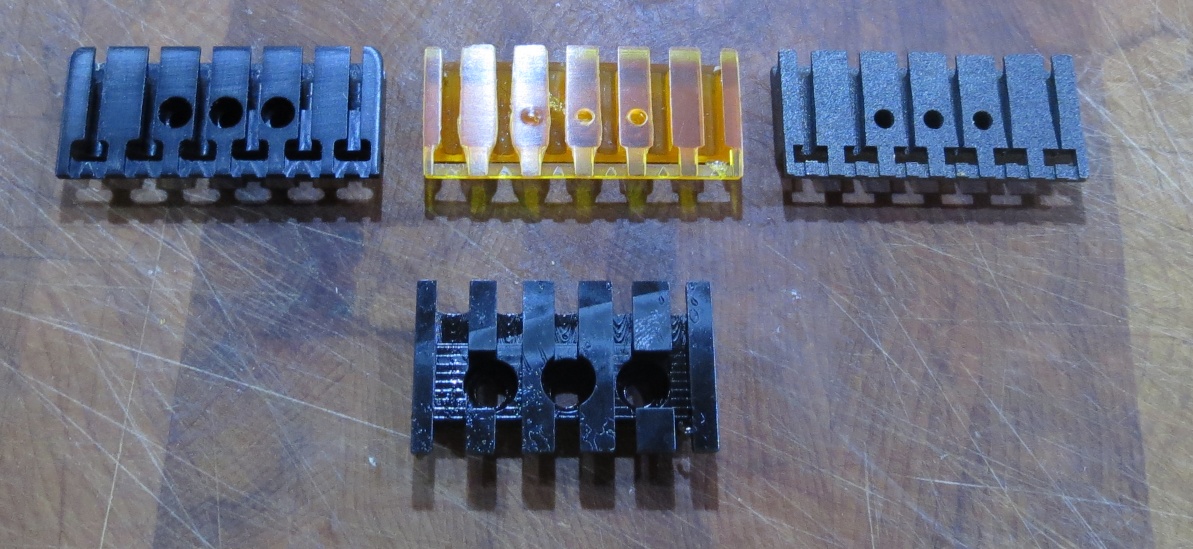

The top row shows 12-string headpieces. The left one was machined out of aluminum and anodized; this is the original. The middle prototype was printed in resin. The right piece was printed by Shapeways, in metal. The bottom piece is a resin prototype for a 5-string narrow headpiece, which is now being printed in metal.

Anyone who wants one of these can now order one from Shapeways and have them in a few weeks, at a reasonable price. The future of manufacturing is here.