More Sculpture Prints

Dec 30, 2013

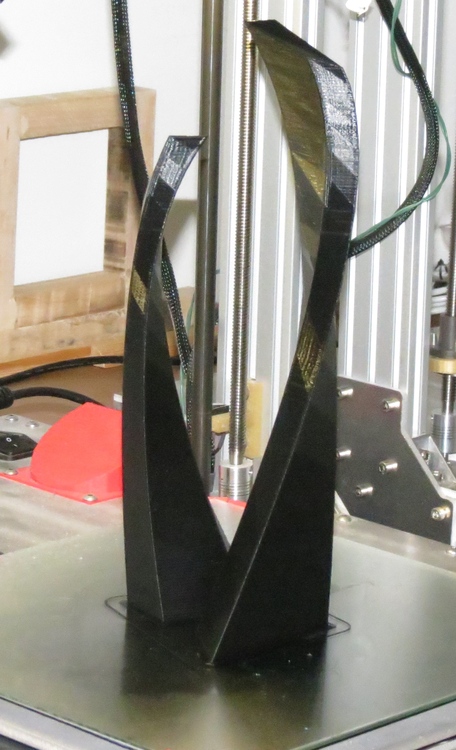

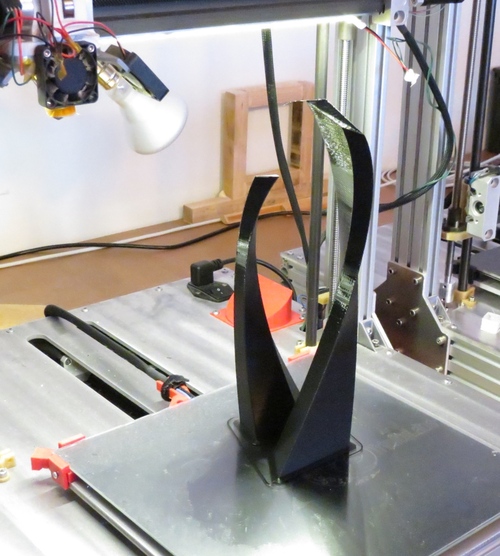

I have been printing more sculptures for/with Chris Curtis. He prepares a 3D model of a sculpture as an STL file, emails it to me, I print it, and then he uses a variety of manual methods (sanding, metallic tape, electroplating, and patinas) to create a small (12" - 24") model of his proposed large (9’) sculpture. When he is finished, the model appears to have been made out of whatever material he intends to use for the final sculpture (copper, stainless steel, etc). He uses the model as part of his presentation when making proposals to clients. It also helps him visualize how he would manufacture the sculpture when the time comes.

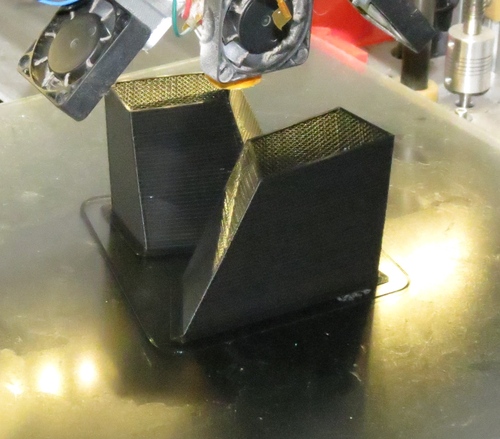

We started out printing this sculpture 12" tall and with 40% infill. This shows the towers during the printing process:

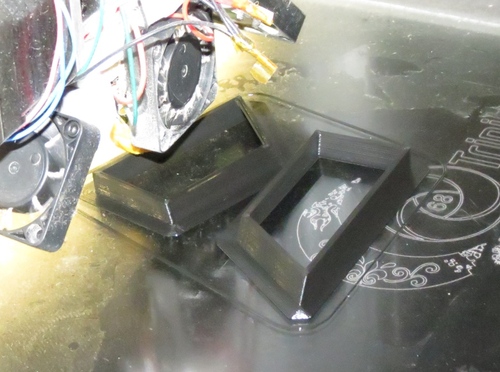

Sponge Holder

Dec 21, 2013

We purchased a new drying rack, on impulse, and found that there no longer was a convenient place to store our sponge. This is what I came up with. The red circles show the locations of semi-circular cutouts to mate with the metal rods.